COATING REMOVAL

BURN-OFF OVEN

All-Color Powder Coating is able to remove the current finish from already coated metal parts, whether it be liquid or powder. This ensures that your parts are completely stripped and prepared properly for the re-coating process.

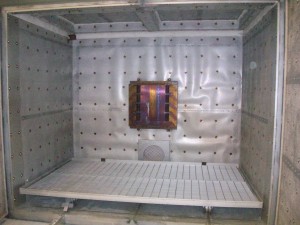

Heat-cleaning ovens, commonly known as burn-off ovens, are used to remove organic materials such as paint, oil, and plastic from metal parts, allowing them to be reused. In the coating industry, hooks and racking fixtures accumulate overspray and lose the conductive surface that is necessary for a proper electrical ground that is crucial for transfer efficiency, even coverage, and to prevent arching that can lead to a possible fire in the powder booth. Rejected or parts to be reworked are also burnt off so a new coating can be sprayed on a clean substrate.

remove organic materials such as paint, oil, and plastic from metal parts, allowing them to be reused. In the coating industry, hooks and racking fixtures accumulate overspray and lose the conductive surface that is necessary for a proper electrical ground that is crucial for transfer efficiency, even coverage, and to prevent arching that can lead to a possible fire in the powder booth. Rejected or parts to be reworked are also burnt off so a new coating can be sprayed on a clean substrate.

Our Advanced Burn-Off Oven by Steelman Industries, Inc. utilizes their patented top-down heating process by introducing the heat into the top of the oven and removing cooler gases and combustible vapor from the bottom of the oven, thus reducing temperature variations creating a consistent burn for paint removal. The Automatic Process Control will automatically adjust the required cycle time to the weight of the load and the amount of combustible material on the parts. This feature measures the temperature at the top and bottom of the oven and monitors the water spray circuit to determine when the oven has finished processing. This control system makes this oven extremely energy efficient and fits with our green philosophy.

T he batch capacity of our burn-off oven is 15’ W X 6’ D X 5’ L. Depending on the amount and type of coating, the cleaning cycle takes approximately 2 hours at a temperature of 800 to 850 degrees. Post cleaning, in most cases, is necessary to remove ash from the burning process.

he batch capacity of our burn-off oven is 15’ W X 6’ D X 5’ L. Depending on the amount and type of coating, the cleaning cycle takes approximately 2 hours at a temperature of 800 to 850 degrees. Post cleaning, in most cases, is necessary to remove ash from the burning process.

Typical applications that use burn-off oven technology include patio furniture, motorcycle/ATV frames, steel rims and fixtures. The paint and powder coating industries also use burn-off ovens to remove the paint from powder coated hooks, racks and fixtures used to hang parts on the line. It’s also used to rework parts that don’t meet quality guidelines.