Monkii-ing Around with Cate Machine

Over the years, we have worked on many projects with our friends at Cate Machine & Welding in Belleville, WI. From railings and racks to industrial frames and carts, almost every job is unique in some way. Cate began a project for one of their existing customers who developed an ultra-portable gym. Based in Boulder, Colorado, MONKII.CO wanted to create a lightweight, colorful gym that could be taken anywhere. Since Cate has been producing and assembling monkii bars minimalist, a wood version of the product, they were the logical choice to help with the new design. As color was significant to the design of this project, Steve Cate thought it would be best for All-Color to work directly with the monkii team. “We have worked with All-Color for many years and because of this partnership, I had no problem introducing them directly to our customer. I knew they would take good care of the monkii team,” stated Steve regarding the decision.

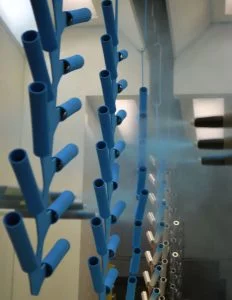

monkii bars 2 being powder coated

To make the unit strong and lightweight, Cate machined the handles from aerospace-grade aluminum. The monkii team wanted to make them colorful and unique so they chose several vibrant colors from Prismatic Powders. Although the colors really stood out, many were quite expensive. To reduce the overall cost, All-Color worked with monkii Jared, their “Chief Napkin Sketcher” to find alternative powders that were less expensive and still very similar in color. Another way All-Color helped the project was to cut costs by developing special racking for the small handles to better utilize line space during production.

monkii bars 2 entering the curing oven

With the base colors selected, the next challenge was to make the visual appearance consistent across all the colors while adding to the durability of the product. Several different clear coat options were sampled until just the right matte clear was discovered and monkii bars 2 was born! They are available now in seven different color options, complete with the matte clear top coat giving them the fun, bright, and very unique monkii look.

The monkii team also wanted to offer a “Naked” version of the handles. This presented its own challenges as the parts need to be handled more carefully throughout the entire machining and coating process to ensure they are coated without scuffs, scratches, fingerprints, or other marks that would be highlighted by the clear powder coat. After sampling a couple different machining processes and several clear powders, we are able to provide handles that will satisfy even their most natural customers.

Thanks to the help of Steve and Jared, this became a rather fun project to work on. We sampled a lot of different colors, overcame some challenges, and in the end the monkii team has the final product they imagined.

monkii bars 2 ready for assembly